SUSTAINABILITY

Through our “Annual Sustainability Report T-GG-F-03”, we demonstrate our alignment with the UN Sustainable Development Goals (SDGs) and the OECD Guidelines for Multinational Enterprises on Responsible Business Conduct.

FUNDAMENTALS

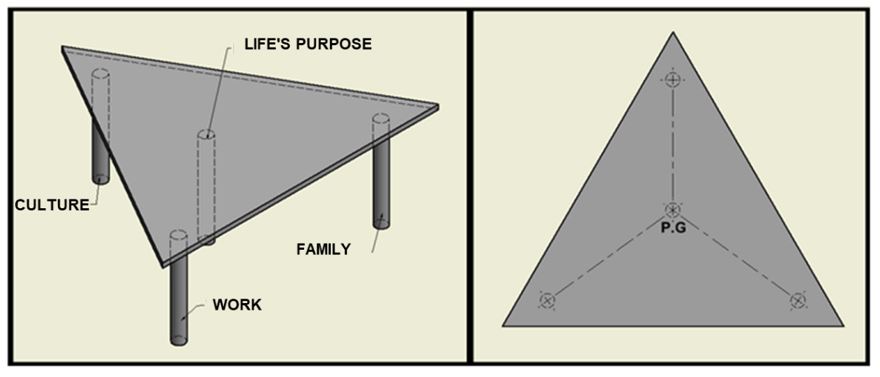

Our Social Pillars

From our perspective, our society is built on four pillars that shape the character and personality of human beings: family, work and culture. Our life’s purpose helps keep us in balance against adversities in some of the other three pillars. Nowadays there is a high risk of being influenced by the media.

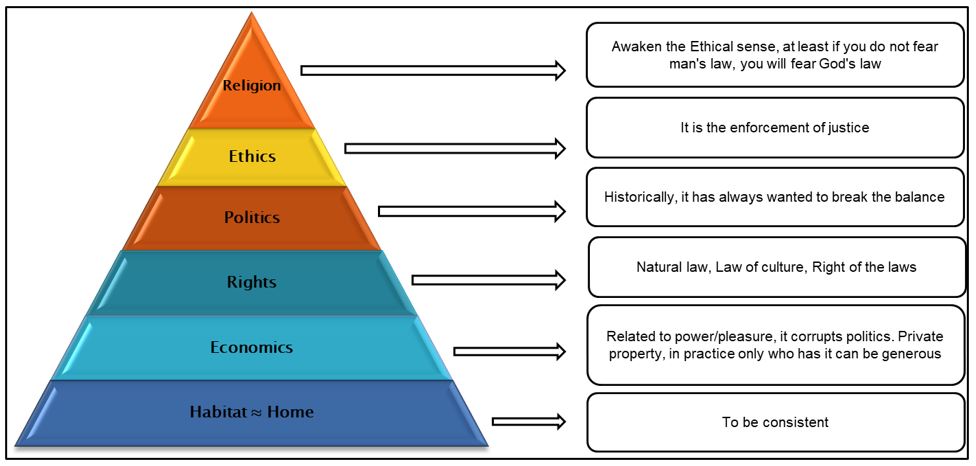

Hierarchies for a healthy and fair society

As envisioned by TAMA, the hierarchies for a healthy and fair society start with religion, then ethics, followed by politics, law, economics, and home. In a society that is neither healthy nor fair, this order of hierarchies may be broken in time of crisis or economic wealth.

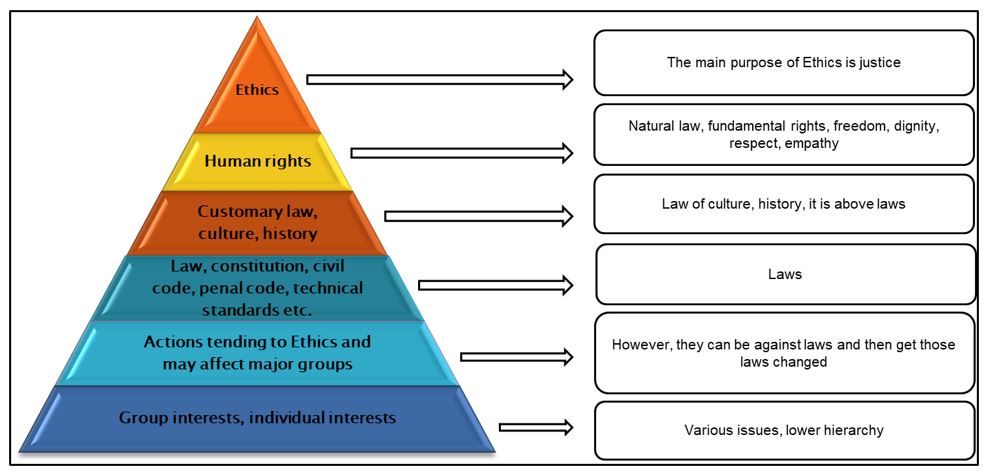

How we prioritize our rights

At TAMA we make our fundamental decisions considering ethics and human rights before personal or group interests.

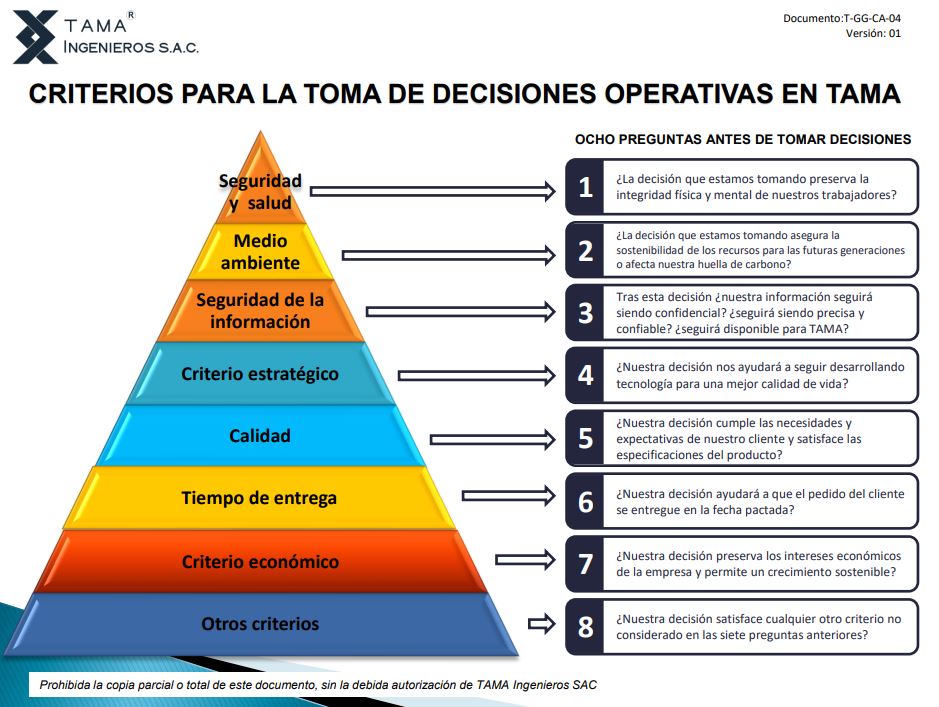

Criteria for operational decisions

Eight criteria are taken into account in our operational decision making, considering, foremost, the value we give to our employees since we are engaged in a very high-risk economic activity: safety and the environment first and foremost.

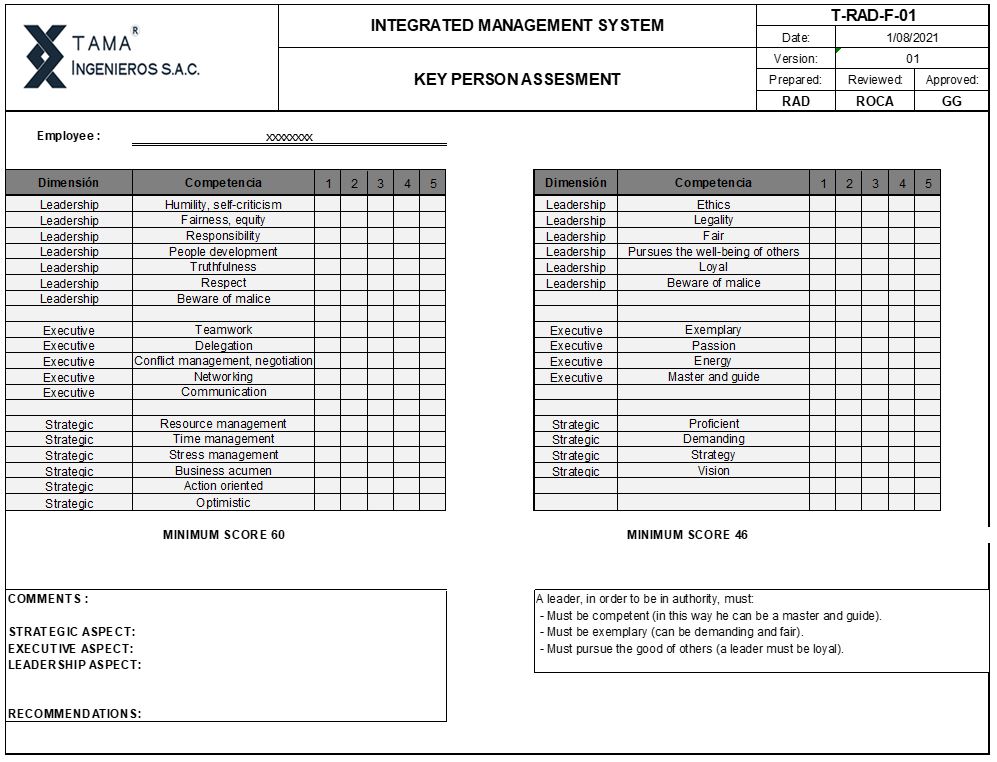

The Leader at TAMA

At TAMA, we evaluate our employees from three perspectives: the strategic dimension, related to the ability to increase the economic value we generate; the executive dimension, related to the ability to adapt our operations to their talent; and the leadership dimension, or the ability to drive people to act for transcendent motivations. If you are interested in joining our team, see below the TAMA leader skills:

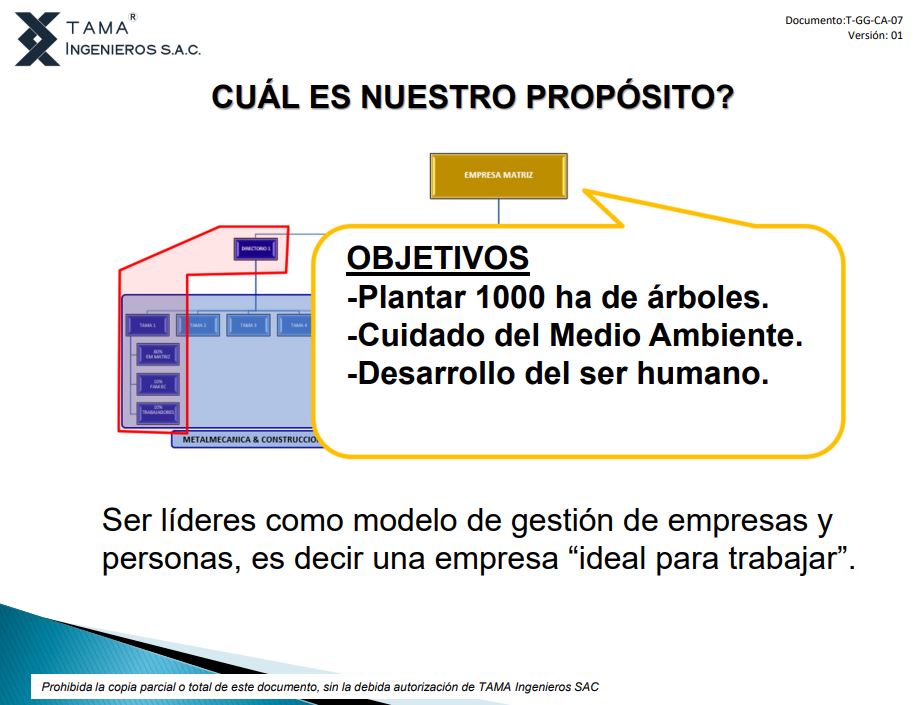

Our purpose

Our purpose is to plant 1,000 hectares of trees, care for the environment, and develop human beings. We pursue to be a model of business and people management, and to become an ideal place to work.

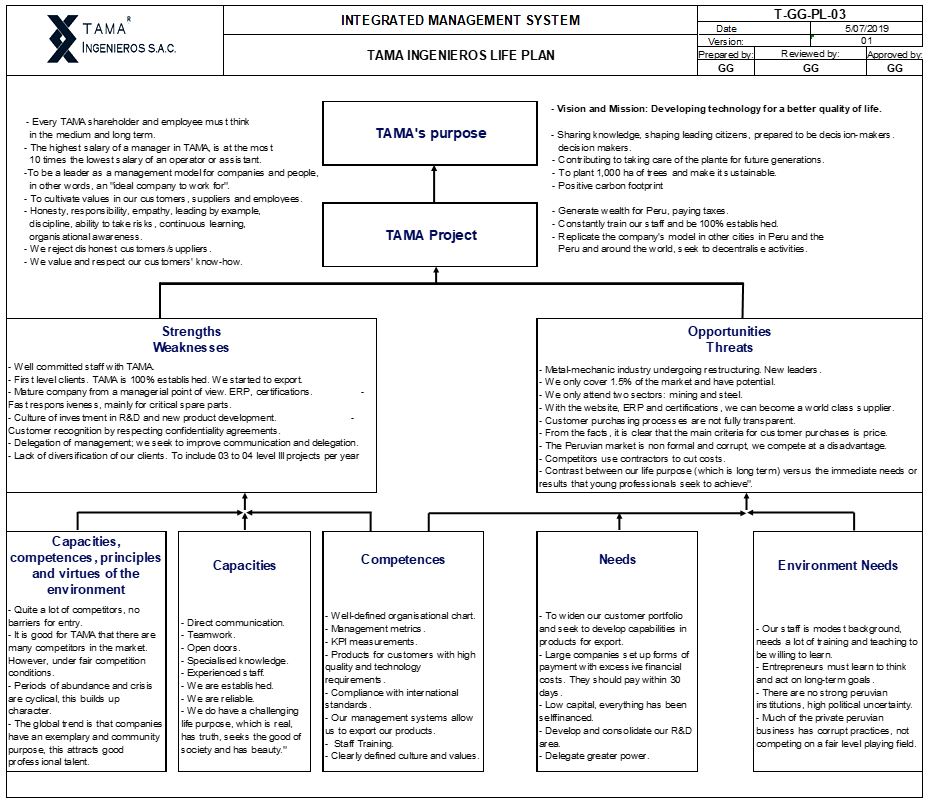

Our Life Plan

We have turned our purpose into a Life Plan as shared below:

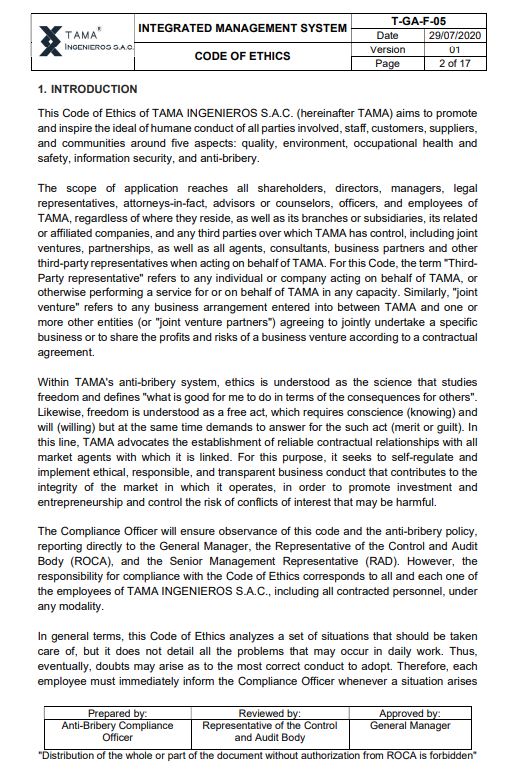

Our Code of Ethics

We promote and inspire the ideal of humane conduct among all stakeholders: employees, customers, suppliers and communities in five areas: anti-bribery, health and safety, environment, information security and quality. Check here our Code of Ethics.

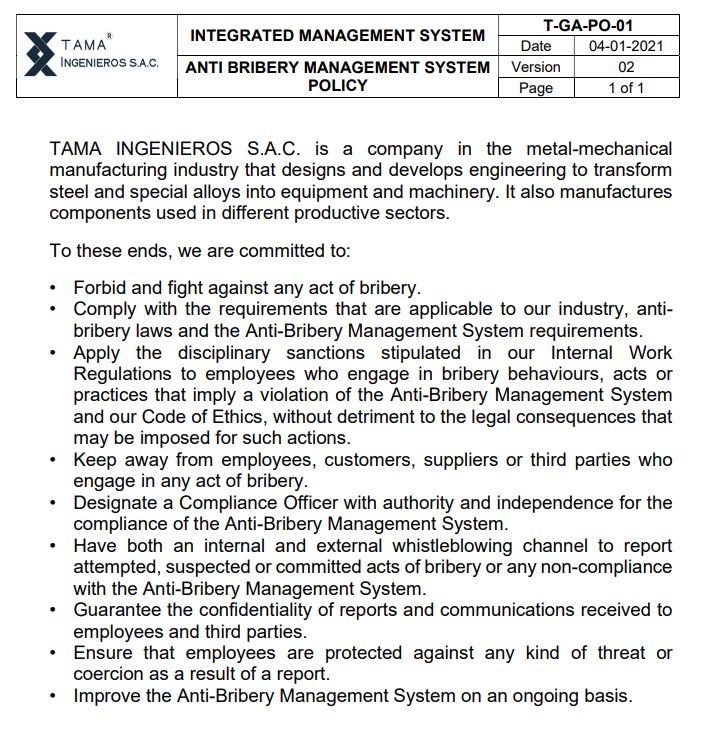

Anti-bribery Management System Policy T-GA-PO-01

TAMA INGENIEROS S.A.C. is a company in the metalworking industry that designs and develops engineering to transform steel and special alloys into equipment and machinery. It also manufactures components used in different productive sectors. To these ends, we are committed to:

INDICATORS

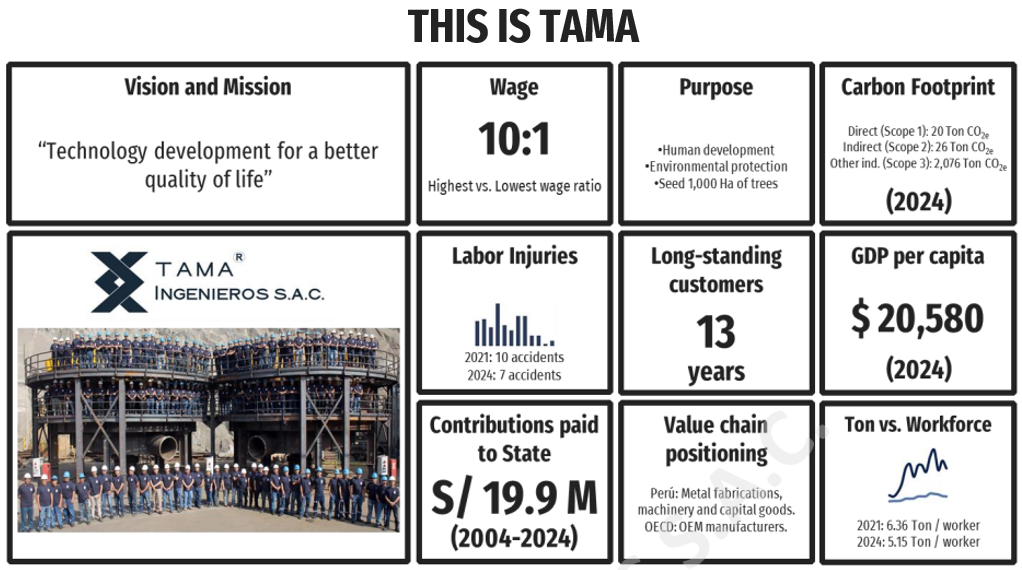

This is TAMA

In this section we summarize the main indicators and guidelines that reflect TAMA’s culture and values and sustainability criteria.

Environment

In this section we share our progress in measuring our carbon footprint, an important milestone in our commitment to sustainability. In addition, we report key indicators demonstrating the reduction in our consumption of electricity, water, paper and wood, as well as the generation of solid waste, contributing to the preservation of natural resources and the mitigation of climate change.

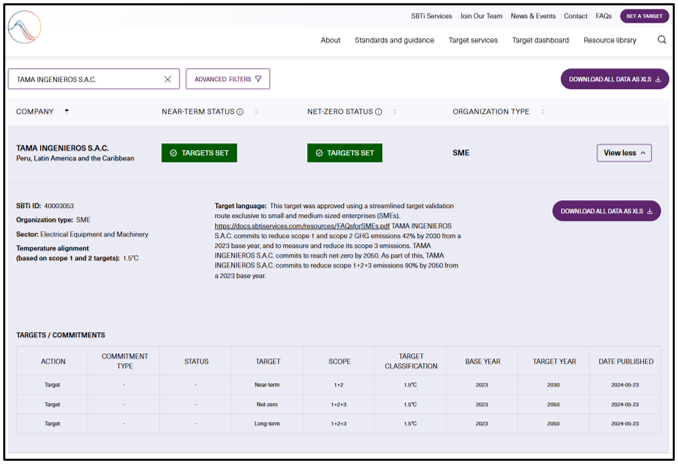

Our science-based targets

As part of our adherence to the SBTi, we have committed to reduce scope 1 and scope 2 GHG emissions 42%, to measure and reduce our scope 3 emissions, commits to reach net-zero by 2050. and to reduce scope 1+2+3 emissions 90% by 2050.

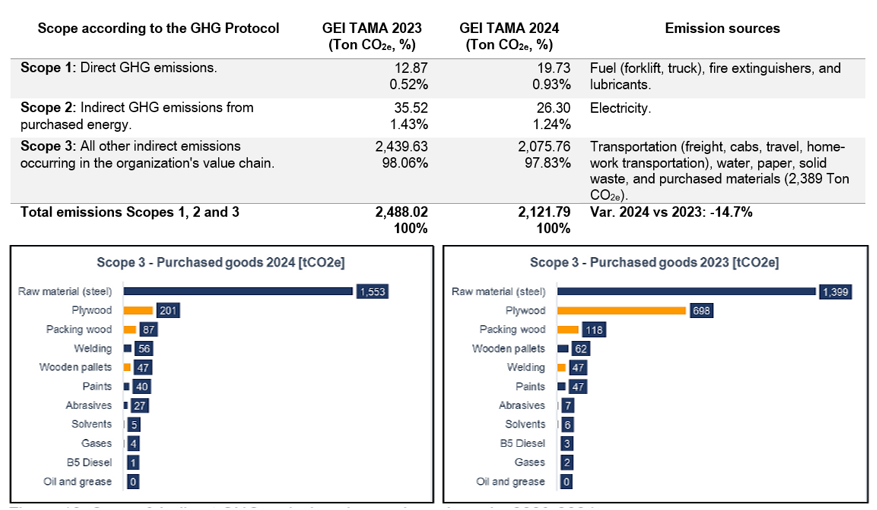

CO2 Emissions

Total greenhouse gas (GHG) emissions generated by TAMA in 2024 amounted to 2,121.79 tons of carbon dioxide equivalent (CO2e), of which 0.93% were direct emissions (Scope 1), 1.24% were indirect emissions from imported energy (Scope 2) and 97.83% were indirect emissions occurring in the value chain (Scope 3). With respect to 2023, Scope 1 emissions increased by 53%, Scope 2 emissions decreased by 26% and Scope 3 emissions decreased by a significant 17%.

Within the indirect emissions of Scope 3, 1,553.31 tons CO2e are due to the purchase of steel raw materials, and 335.51 tons CO2e originate from the purchase of wood and its derivatives used for packaging (plywood, wood, and pallets), as shown in Figure 10.

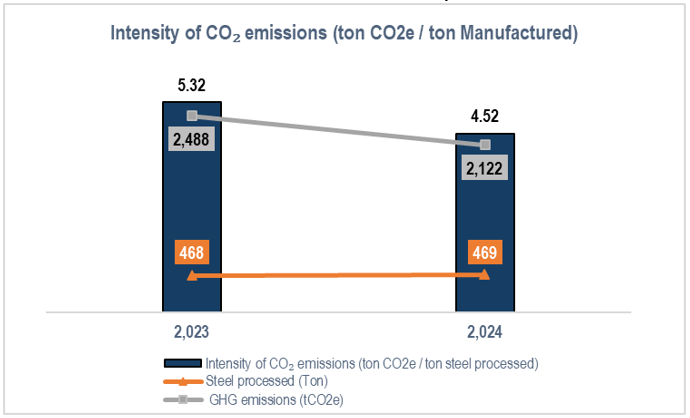

Intensity of CO2 emissions

In relation to the intensity of CO₂ emissions – i.e., the amount of carbon dioxide equivalent emitted per ton of processed steel (scopes 1, 2 and 3) – in 2024 TAMA achieved a significant reduction of 14.9% compared to the previous year, decreasing from 5.32 to 4.52 tons of CO2e per ton of steel.

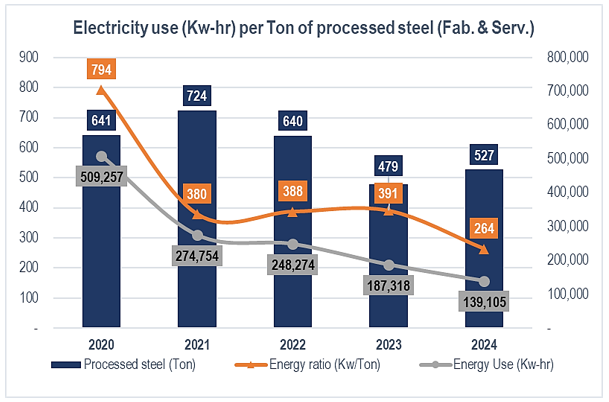

Electricity Consumption

At TAMA, we have worked on optimizing our electricity consumption, achieving in 2024 a 32.4% reduction in energy intensity, with a consumption of 264 kWh per ton of processed steel.

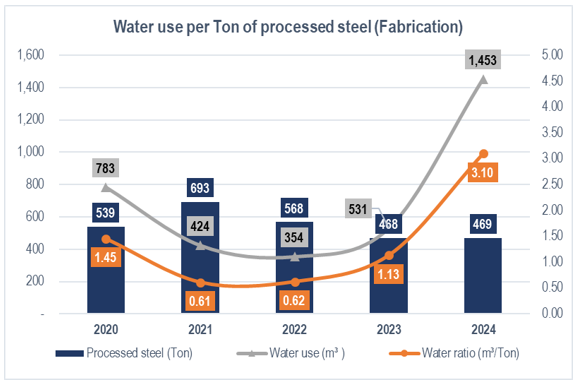

Water Consumption

SDG 6 on “Clean Water and Sanitation” demands us to be more efficient in water use to achieve universal coverage. Our water consumption per ton of production increased from 1.45 m³ in 2020 to 3.10 m³ in 2024. However, in 2024, TAMA experienced a notable rise in water consumption, primarily due to unauthorized use of our public network connection by third parties through illicit taps.

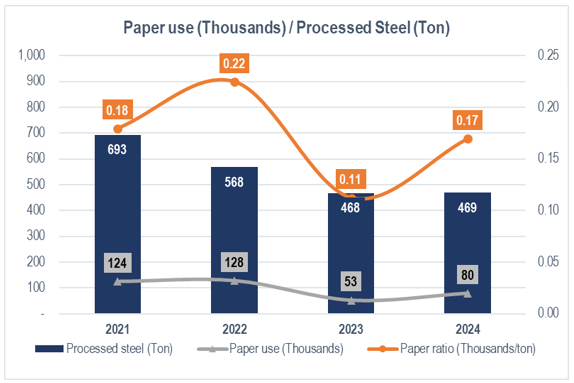

Paper Consumption

In 2024, paper consumption at TAMA, used mainly for printing manufacturing drawings and records, increased from 0.11 to 0.17 thousand per ton of steel due to specific requirements from some customers who request their quality dossiers in physical format.

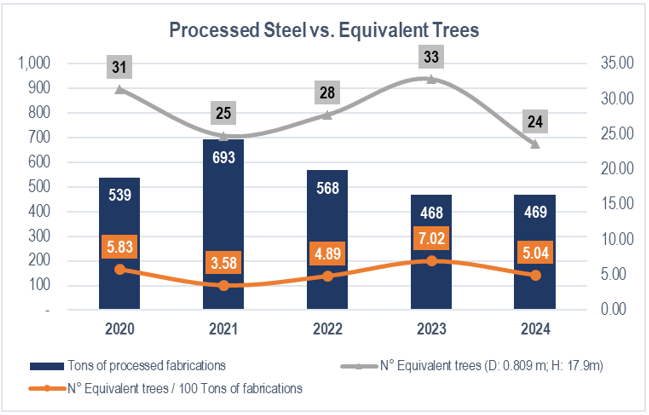

Wood consumption for packaging

To meet our customers’ packaging standards, in 2024 for every 100 tons of steel fabrications five 0.81 m diameter x 17.90 m high trees had to be felled. In 2024, we set out to restrict the use of wood exclusively to pallets with standard dimensions of 1,300 mm x 1,100 mm, eliminating the use of wooden slats or beams for packaging our fabrications . This initiative enabled us to reduce wood consumption by 28% compared to the previous year.

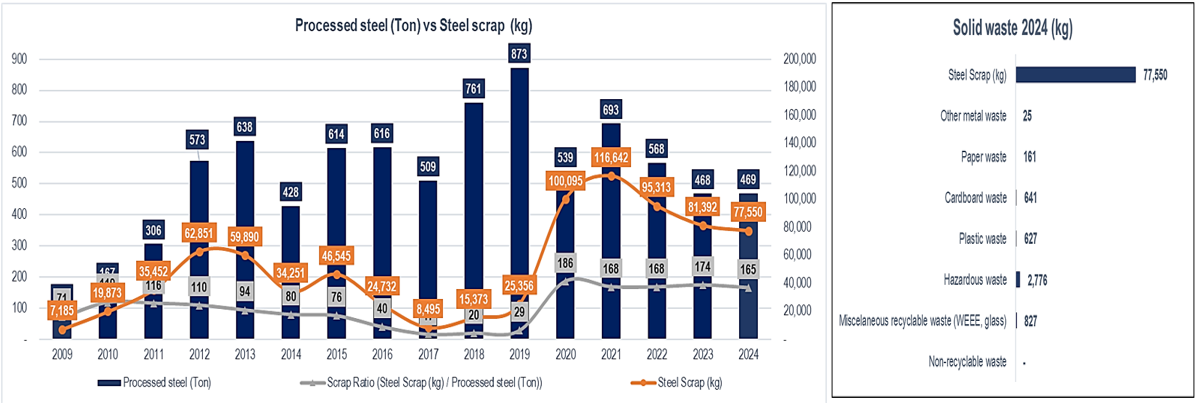

Solid waste

Since 2009, TAMA has been carrying out statistical control of the solid waste generated by our operations. In the 2020-2023 period, the ratio of solid steel waste generation has remained stable between 167 and 185 kg of steel waste per ton processed.

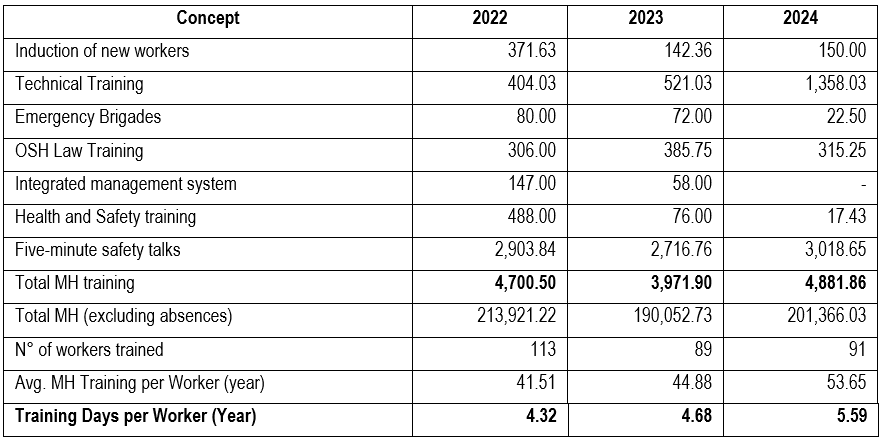

Human and labor rights

SDG 10 on reducing inequalities states that it is necessary to distribute resources equitably, and to invest in education and capacity building. Since 2018 when TAMA began the process to achieve ISO 9001, ISO 14001, ISO 45001, ISO 27001, and ISO 37001 certifications, we have progressively increased training for employees and operators. Thus, for instance, in 2024 TAMA workers attended an average of 5.59 days of technical training, staff induction, and five-minute safety talks, compared to 4.68 annual days of training received in 2023.

In line with SDG N° 8 (Decent Work and Economic Growth) and SDG N° 10 (Reducing Inequalities), and with our Life Plan T-GG-PL-03, the highest salary of a manager at TAMA is, at most, ten times the lowest salary of an operator or assistant. In addition, at TAMA, all salaries are paid on payroll with the real wage and we do not hire minors

Health and safety

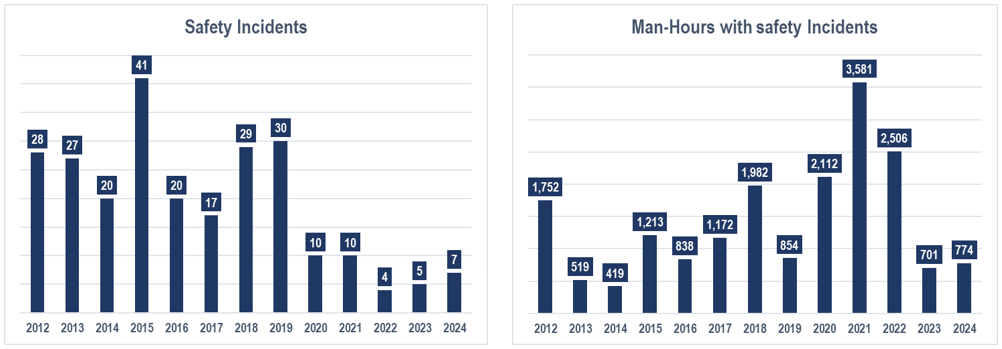

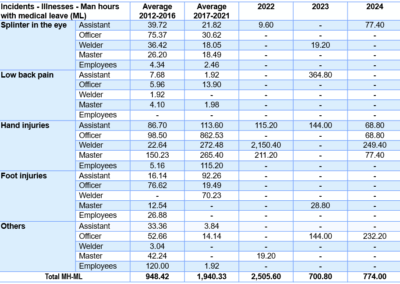

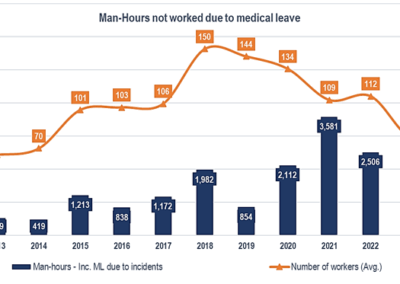

At TAMA we have been managing our safety indicators since 2012 and, as a result of the safety training carried out, in the last five years we have significantly improved the frequency and severity rates of incidents.

- Injuries, severity, and frequency

In 2024, the severity of sick leave in terms of man-hours increased compared to 2023, particularly in incidents involving blows, sprains, or cuts to the hands, considering that 98% of safety accidents in the metalworking sector occur among workers.

Quality and customer satisfaction

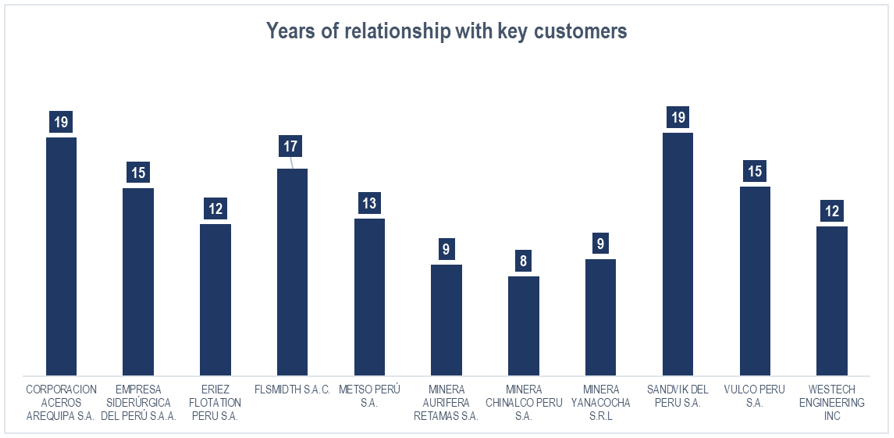

Long-standing customer relationships

The long standing of our customers, the qualifications obtained over the years in different audits, along with the evolution of the steel tons produced by each worker reflect that in TAMA we strive for the development of friendship, looking forward to the medium and long term, while preserving the know-how of our customers.

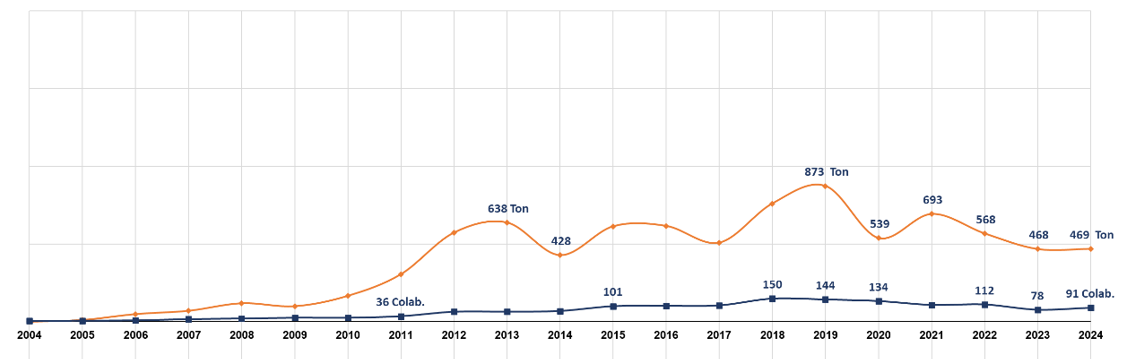

Management and manufacturing capabilities

We are committed to keep a maximum employee to operator ratio of 1:1.5 (i.e. a maximum of 13 operators for every 10 employees) and to not using contractors. This mix of management and manufacturing capacity is what makes it possible, for example, to transform 469 tons of steel in 2024 with 91 workers: 53 operators and 38 employees.

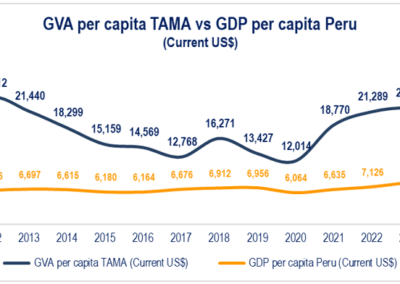

Financial sustainability

At TAMA, since 2022 we measure gross domestic product per capita, an economic index that also reflects TAMA’s efforts towards sustainable development goals such as eradicating poverty, decent work, and economic growth.

In 2024 TAMA’s Gross Value Added per capita (GVApc) was US$ 20,580, 2.4 times the Peruvian GDP per capita, which is estimated at US$ 8,520 according to official data.

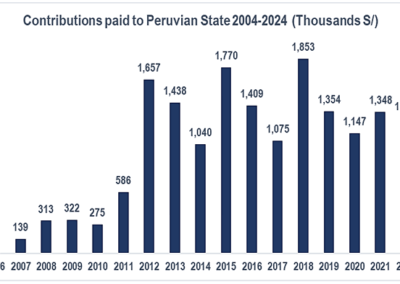

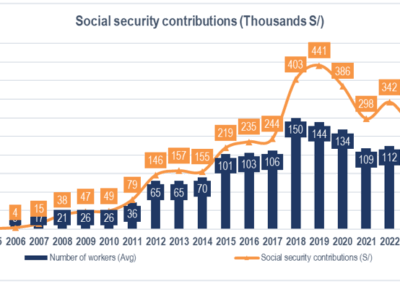

In line with Chapter XI “Taxation” of the OECD guidelines, which emphasizes that it is important for companies to contribute to the public finances of countries making timely payment of their tax liabilities, between September 2004 and December 2024 TAMA has contributed to the Peruvian State S/. 19,906,179 including value added taxes, income tax, social security, workers’ profit sharing, extraordinary profits, and a productivity bonus.

Technology and Innovation

In this section, we provide information on confidentiality and advances in technology and innovation.

Confidentiality agreements

TAMA aligns itself with Chapter IX of the OECD Guidelines on Science, Technology and Innovation which states that companies must comply with applicable national laws and requirements, including privacy and data protection requirements and export control regulations, and that digital security is a shared responsibility across all stakeholders, including businesses, customers, and governments

Research & Development

Visit our R&D section to see our projects in technology, innovation and development..

Stakeholders

Exports

SDG target 17.11 calls for “Significantly increase exports from developing countries“. At TAMA, we are working to position Peruvian metalworking products abroad and, as a demonstration of this, we have continued to steadily increase our exports since 2018.

Note: 2024 TAMA exports do not include US$ 253,000 sold to the Peruvian subsidiary of a Canadian client that were finally exported to Canada.

Calle 03 Mza. A Lote. 6B, Urbanización Barbadillo, Ate, 150103- Lima – Perú.

Calle 3, Mz.B, Lt.1, Urbanización Barbadillo, Ate, 150103, Lima, Perú

2023 | TAMA INGENIEROS S.A.C. ® | www.tamaingenieros.pe