SERVICES

WHAT WE OFFER:

1. Plasma or oxyfuel plate cutting

2. Shearing and band sawing of shapes and sections

3. Plate rolling

4. Welding, with certified welders

5. Machining

6. Vibrating stress relief

7. Shot blasting and painting

8. Mechanical assembly

9. Repair and recovery of components

10. Handling

-

Increased plant capacity

-

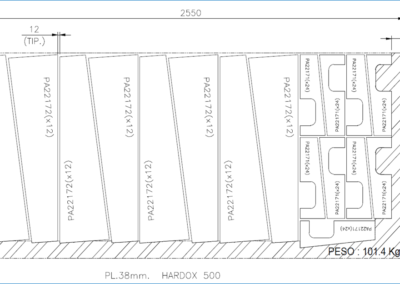

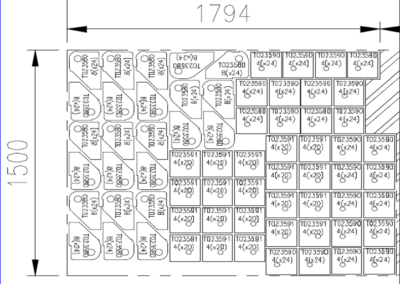

Optimization of materials, minimum waste/scraps

-

Reduced risk due to loss of poorly machined materials

-

Burr free cuts

-

Decrease in logistics and warehouse management

-

Warranty

-

Protection of your know-how

-

Quality

-

Improved delivery times for your final product.

VALOR AGREGADO

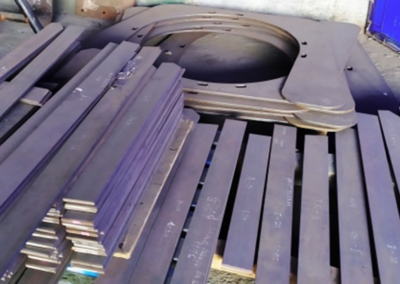

PLATE CUTTING SERVICE

PLASMA AND OXY CUTTING SERVICE

HYPERTHERM CNC SYSTEM

CUTTING CAPACITY:

Max. thickness: 63mm-Plasma

Max. thickness: 200mm-Oxycutting

CUTTING TABLE DIMENSIONS:

Width x Length: 3.20m x 7.60m

CNC SYSTEM N°2

CUTTING CAPACITY:

Max. thickness: 38mm-Plasma

Max. thickness: 200mm-Oxycutting

CUTTING TABLE DIMENSIONS:

Width x Length: 2.90m x 7.60m

For cutting of:

– Carbon steel

– Stainless steel

– Wear plate

BEAMS CUTTING SERVICE

BAND SAW CUTTING MACHINE

CUTTING CAPACITY:

Max. beam height : 14″

Max. beam width : 24″

Sawing angle: 0° – 45° – 60

SHEAR, PUNCH & NOTCHING SERVICE

STEEL PLATE ROLLING SERVICE

DAVI PLATE ROLLING MACHINE

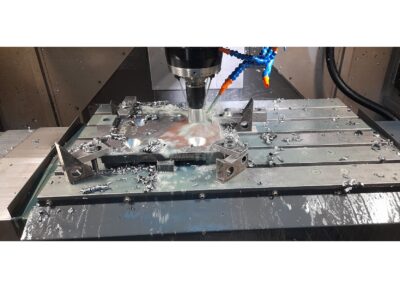

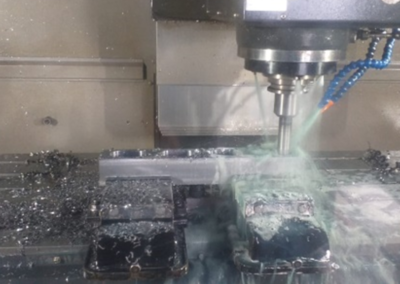

MACHINING SERVICES FOR METALWORKING

CNC MACHINING CENTERS

KAFO CNC MACHINING CENTER

Model: DV-9B

CAPACITY:

Travel 900x600x600 (X,Y,Z)

Max. load: 650 Kg.

KAFO CNC MACHINING CENTER

Model: VMC-1370

CAPACITY:

Travel 1400x700x700 (X,Y,Z)

Max. load: 1500 Kg.

.

LATHE MACHINES

WELDING SERVICES

OUR STAFF IS QUALIFIED WITH THE FOLLOWING COMPETENCES:

-

AWS – CWI certified welding inspectors.

-

NDT Level II Inspector for Dye Penetrant Testing certified ASNT-SNT-TC-1A.

-

NDT Level II Inspector for Magnetic Particle Testing certified ASNT-SNT-TC-1A.

-

Homologated welders, in different processes and positions for welding application.

-

We have a range of approved procedures for different types of welding joints, included in special materials, e.g. A-36 with AISI 4140, etc.

VIBRATORY WELDING STRESS RELIEF SERVICE

We developed a procedure for cold stress relief by vibrations, which has been approved in major projects performed in Peru.

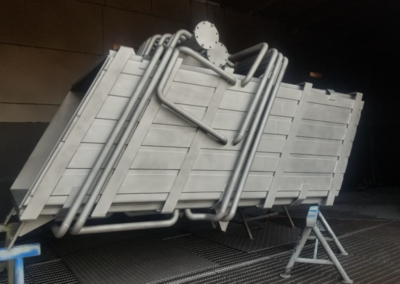

SHOT BLASTING SERVICE

01 SEMI-AUTOMATIC SHOT BLASTING CHAMBER.

Dimensions: 16.0 m x 8.0 m x 7.0 m (height).

Service scope:

- Qualified staff, with all the safety and environmental protection measures.

- Development of shot blasting and painting procedure prior to activity launching.

- Shot blasting according to standards SSPC-SP-5, SSPC-SP-6, SSPC-SP-10, anchor thickness from 1.5 to 3 mil, upon request.

- Spherical and angular shape steel shot, according to SAE J827 and J1193 standards.

- Shot blasting and painting can include chloride testing, air quality, dust level, conductivity and particle size, roughness profile, air outlet pressure and nozzle diameter, according to SSPC guide 15; ASTM 4285; ASTM 4417, upon request.

Applied material: Steel shot.

- Near-white blast cleaning according to SSPC-SP-10.

- White metal blast cleaning according to SSPC-SP-5

- Commercial blast cleaning according to SSPC-SP-6

PAINTING AND COTATING SERVICE

OVER 1,800 M² OF PAINTING FACILITIES ARE AVAILABLE.

Scope of service:

- Qualified personnel, with all safety and environmental protection measures.

- Shot blasting and painting procedure development before starting the process.

- Upon request, we have experience in Mist Coat (Thin coat), Stripe Coat processes, as required.

- Shot blasting and painting can include chloride testing, air quality, dust level, conductivity and particle size, roughness profile, air outlet pressure and nozzle diameter, according to SSPC Guide 15; ASTM 4285; ASTM 4417, on request.

- Adherence test specimens, Holiday tests, as per requirement.

- Release of dry film thicknesses will be performed according to SSPC-PA2, level V.